A point of focus during health inspections is the verification of sanitary and safety standards. Inspectors assess compliance with regulations to ensure public health protection.

Ensuring food establishments uphold proper hygiene is paramount for public safety, a primary area scrutinized during health inspections. Inspectors typically conduct thorough reviews of restaurants, grocery stores, and food processing plants, looking for potential hazards that could lead to foodborne illnesses.

They examine kitchen cleanliness, employee hygiene practices, and proper food handling methods. The temperature at which foods are stored and cooked is also a critical checkpoint, as it can significantly affect the proliferation of harmful bacteria. Documentation and record-keeping play a crucial role; inspectors verify that businesses track food sources and maintain logs for equipment performance, particularly for refrigerators and cooking appliances. This vigilance helps in early detection of risks, contributing to the community’s overall well-being and trust in local food services.

Introduction To Health Inspections

Health inspections are critical for maintaining public safety. They prevent illness by ensuring that facilities adhere to health codes. Inspectors look at restaurants, schools, and hospitals. They protect us from health hazards not always seen by the naked eye. A successful inspection promotes trust. It shows that a business cares about its customers’ well-being.

Purpose Of Regular Inspections

Regular health inspections serve several purposes:

- Identify potential issues before they become outbreaks.

- Ensure compliance with laws and regulations.

- Enhance food safety and prevent foodborne illnesses.

- Provide ongoing education and guidance to operators.

Impact On Public Health And Safety

Health inspections directly influence public health. Through these inspections:

- Facilities maintain clean conditions.

- Proper protocols are enforced.

- Health risks are minimized, protecting community health.

A consistent inspection program deters negligence. It ensures establishments meet the standards needed to keep everyone safe.

Identifying Critical Control Points

During health inspections, focus is key. Identifying critical control points (CCPs) is a must. These are stages in food handling where risks can be prevented, reduced or eliminated. They are vital for safe food service.

Analysis Of Food Handling Processes

The journey of food from farm to fork is complex. Each step must be analyzed. The goal is to pinpoint where intervention is essential. Here’s what inspectors scrutinize:

- Receiving: Is the food source safe and reliable?

- Storing: Are proper temperatures maintained?

- Preparing: Are foods cooked to the right temperatures?

- Serving: Is food handled with care to avoid cross-contamination?

- Cleaning: Are all areas sanitized effectively?

Hazard Prevention Strategies

Preventing hazards is better than fixing problems later. The following strategies are essential:

- Education: Train staff on food safety.

- Monitoring: Keep an eye on every critical point.

- Corrective Actions: Know what to do if something goes wrong.

- Verification: Regular checks ensure methods work.

- Documentation: Keep records updated for accountability.

Temperature Controls

When it comes to health inspections in food establishments, temperature controls are critical. They play a pivotal role in preventing foodborne illnesses. Let’s explore this point of focus and understand its significance.

Importance Of Keeping Food Safe

The safety of food is non-negotiable. Pathogens thrive at certain temperatures, turning food into a health hazard. Strict temperature regulations keep these risks at bay. Maintaining the right temperatures can halt bacteria growth, ensuring each meal remains safe to eat.

- Bacterial growth minimization: Below 5°C or above 60°C limits risks.

- Toxin prevention: Correct temperatures stop dangerous toxin production.

- Longer shelf-life: Food stays fresh and consumable for longer periods.

Monitoring Storage And Cooking Temperatures

Constant vigilance is essential in food temperature monitoring. Every stage, from storage to serving, demands attention. This diligence ensures a meal’s safety and quality from the fridge to the fork.

| Stage | Temperature Range | Action |

|---|---|---|

| Receiving | Below 5°C | Check deliveries immediately. |

| Storage | 0°C – 5°C | Monitor fridges daily. |

| Cooking | Above 74°C | Use a food thermometer. |

| Serving | Keep hot foods >60°C | Use warming equipment. |

A comprehensive approach includes:

- Using calibrated thermometers for accuracy.

- Logging temperatures regularly.

- Training staff on proper procedures.

Personal Hygiene Practices

Personal Hygiene Practices stand at the forefront of health inspections. Ensuring each member of the team maintains high standards is crucial. This vigilance keeps both staff and customers safe. Health inspections keenly evaluate these practices.

Handwashing Protocols

Proper handwashing is the cornerstone of personal hygiene in any establishment. Inspectors closely observe whether employees wash their hands:

- Before food preparation

- After restroom use

- When switching tasks

Inspectors also check for posted handwashing signs and whether staff understand the correct technique:

- Wet hands with clean, running water

- Apply soap and lather well

- Rub hands for at least 20 seconds

- Rinse thoroughly

- Dry with a clean towel

Employee Health Policies

Health inspections scrutinize employee health policies diligently. Key areas include:

| Policy Area | Expectation |

|---|---|

| Illness Reporting | Staff must report symptoms promptly. |

| Exclusion from Work | Sick employees should not handle food. |

| Return to Work | Clear guidelines determine when staff can return. |

Evaluators ensure staff are aware of the signs of foodborne illness. These include:

- Vomiting

- Diarrhea

- Fever

Training records and compliance logs are often checked to confirm policies are in practice.

Cleaning And Sanitation

Cleaning and sanitation stand as critical points during health inspections. A clean environment lowers health risks. Proper sanitation ensures safety for everyone. Inspectors look for cleanliness in kitchens, restrooms, and dining areas.

Effective Cleaning Schedules

Health inspections prioritize effective cleaning schedules. An organized plan ensures regular cleaning tasks happen without fail. This prevents buildup of grime and bacteria.

- Daily cleanup after service

- Weekly deep cleaning of equipment

- Monthly inspection of hard-to-reach areas

Schedules should include staff assignments. They must cover all areas of the establishment.

Cross-contamination Prevention

Preventing cross-contamination is vital for safety. It involves separating raw items from cooked foods. Proper storage and handling methods are key.

| Storage | Handling | Tools and Equipment |

|---|---|---|

| Use designated shelves | Wash hands thoroughly | Clean cutting boards after use |

| Keep raw meat at the bottom | Change gloves often | Separate tools for different food types |

Training for staff on contamination is essential. Signs reminding of best practices are helpful too.

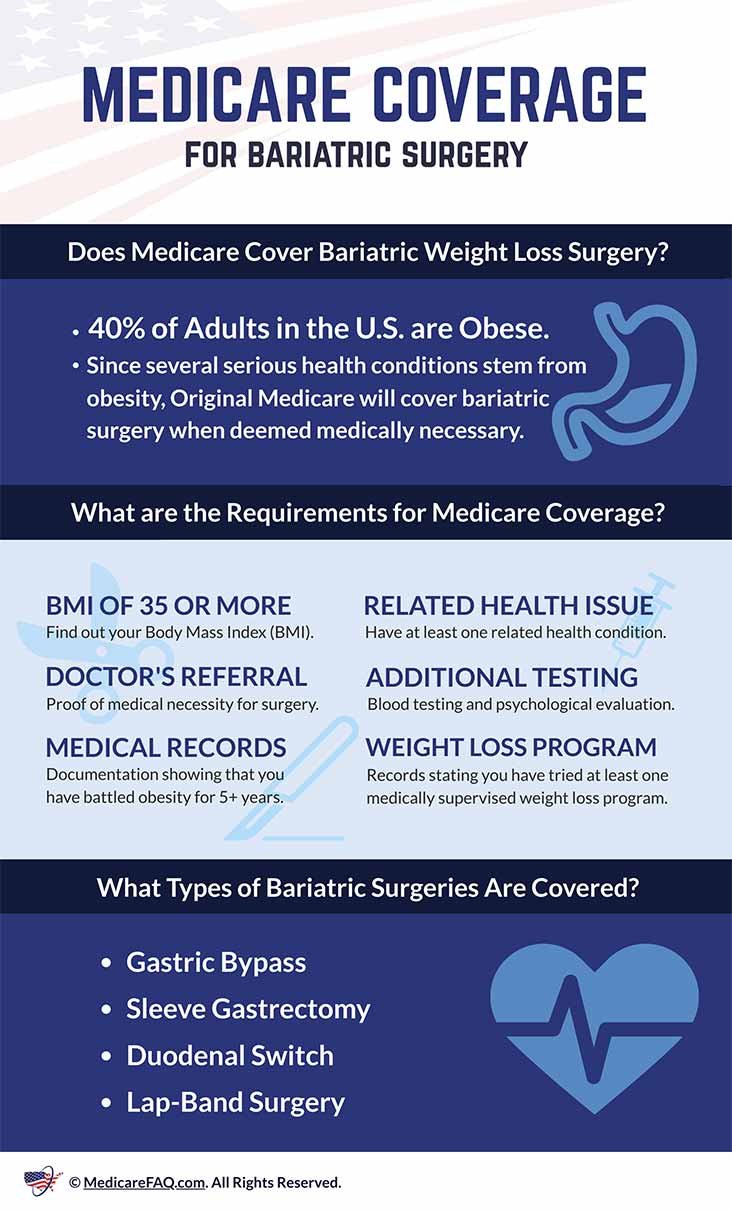

Credit: www.fooddocs.com

Equipment And Facility Conditions

Health inspections are a pivotal moment for any facility handling food. Inspectors check many things. One key point of focus is Equipment and Facility Conditions. This includes how appliances work and if the place is clean and solid. Let’s dive into these critical elements.

Maintenance Of Essential Appliances

During inspections, one vital check is how well appliances work. Health inspectors look at equipment related to food safety. The list includes fridges, freezers, ovens, and stoves. They must all be working right to prevent food from spoilage.

- Temperature controls must keep food safe.

- Appliances must be clean and not broken.

- Regular checks and fixes are a must for meeting standards.

Structural Integrity And Cleanliness

The condition of the facility also matters. Inspectors review the building’s structure. It includes walls, floors, and ceilings. All must be in good shape and clean.

Cleanliness helps stop the spread of germs. This keeps both staff and patrons safe.

| Area | Inspection Focus |

|---|---|

| Walls | Must be free of cracks and easy to clean |

| Floors | Should be smooth, robust, and have no puddles |

| Ceilings | Need proper ventilation to prevent condensation |

Pest Control And Management

Pest Control and Management ranks high during health inspections. Clean facilities deter pests. Health inspectors look for pest issues. Good pest control ensures safety and cleanliness.

Identifying Signs Of Infestation

Spotting pests early stops bigger problems. Inspectors check for droppings, nest materials, and damage to stock. Signs can be subtle. Training staff to recognize these signs is crucial.

- Droppings: Small, dark, rice-shaped marks.

- Nests: Materials like shredded paper or fabric.

- Damage: Holes in walls or gnawed packaging.

Integrated Pest Management Practices

Integrated Pest Management (IPM) combines different methods. It’s a smart approach to pest control. It keeps facilities safe. Inspectors favor places using IPM.

| IPM Steps | Actions |

|---|---|

| Inspect | Regularly check for signs of pests. |

| Identify | Correctly figure out what pest is present. |

| Prevent | Seal entry points and manage waste effectively. |

| Control | Choose safe, effective methods to eliminate pests. |

Proper Food Storage And Labeling

Proper Food Storage and Labeling stands as a critical point of focus during health inspections. This vital aspect ensures food safety and reduces the risk of contamination. Let’s break down the key elements of this process under two main headers.

Organizing Storage Areas

Organization is crucial in storage areas. Well-organized storage prevents cross-contamination and simplifies inventory management.

- Raw meats on lowest shelves

- Use clear containers for visibility

- Designate sections for different food types

Stack items neatly with space between them to allow airflow and easy access. Temperature control plays a big role, so ensure cold storage units are at correct temperatures.

Adherence To Labeling Regulations

Accurate labeling is non-negotiable. Labels provide essential information and help track food freshness.

| Label Detail | Importance |

|---|---|

| Product Name | Identifies the food |

| Date of Storage | Tracks food safety |

| Use-by Date | Prevents spoilage |

Use waterproof labels in cold storage to prevent smudging. Update labels during re-packaging to maintain accurate information on food items.

Documentation And Record Keeping

Strong documentation and record keeping are crucial during health inspections. These records show proof of a health-conscious organization. They track efforts to meet the highest safety standards. Inspectors look at these records to gauge an organization’s commitment to health regulations.

Importance Of Up-to-date Logs

Keeping logs up-to-date ensures that information is current and relevant. It reflects a proactive approach to health management. Regular updates to logs can help identify trends and address issues quickly. This vigilance can prevent health risks from escalating.

- Monitor employee training – Confirm that staff consistently receives up-to-date health training.

- Track cleaning schedules – Verify that facilities undergo regular and thorough cleaning.

- Maintain equipment use logs – Record when and how often equipment gets maintenance checks.

- Control inventory – Ensure that product rotation follows first-in, first-out (FIFO) principles.

Legal Requirements For Tracking

Maintaining records is not just a good practice; it’s often a legal obligation. Comprehensive logs can prove compliance with health laws. These records can include detailed accounts of incidents, corrective actions taken, and audit trails. They serve as legal documents during litigations and compliance reviews. The table below depicts commonly required records.

| Documentation Type | Required By Law |

|---|---|

| Employee Health Records | Yes |

| Training Records | Yes |

| Cleaning and Sanitation Logs | Varies by Jurisdiction |

| Temperature Control Logs | Yes |

Businesses should understand what documentation they need. They should make sure records are accessible, organized, and preserved according to legal standards. Such diligence can simplify the inspection process and demonstrate a commitment to health and safety.

Credit: unitymindful.com

Training And Staff Knowledge

When health inspectors visit, they zero in on how well staff understand safety. They ask about handwashing, food storage, and cooking temperatures. A mistake can mean germs spread in the kitchen. So, training is key. Let’s explore why ongoing learning and staff knowledge are big deals for health inspections.

Continual Education On Food Safety

Regular training sessions keep the team updated on food safety. They learn about clean workspaces and the right way to handle food. Interactive sessions, like quizzes and role-plays, make learning stick. Here’s how good education programs work:

- Up-to-date materials – They include the latest food safety laws.

- Interactive – Staff can practice what they’ve learned.

- Certifications – Cooks and servers earn them after passing tests.

Assessing Staff Comprehension

Inspectors talk to staff to see if they know their stuff. They ask questions to check understanding. It’s not just about memorizing facts—it’s applying them. Here’s what inspectors look for:

| Area | Knowledge Checked |

|---|---|

| Cleaning | Correct use of cleaning agents |

| Food Storage | Temperatures and methods for keeping food safe |

| Cooking | Temperatures to kill germs |

The table shows how each team member must be a safety expert in their work area. Inspectors ensure everyone is on the same page. This helps stop mistakes that could make people sick.

Emergency Preparedness

When a health inspector visits, they check many things. One vital area is emergency preparedness. Places that make or sell food must be ready for emergencies. This means knowing what to do if something goes wrong. This could be a food recall or failing an inspection. Being ready helps keep everyone safe. Let’s dig into two main points.

Handling Food Recalls

Food recalls can happen. They mean something is wrong with the food. It could make people sick. Places with food must know how to handle this. They need a plan to stop using the food and tell the right people. Here is what they usually do:

- Stop serving the food right away.

- Remove the food from the shelf.

- Tell the team about the recall.

- Follow the steps to send the food back.

Doing these things quickly is important. It helps keep everyone safe.

Response To Health Inspection Failures

Sometimes, places fail health inspections. If this happens, they must act fast. A good response includes:

- Reviewing the report to see what went wrong.

- Training staff to fix these issues.

- Making changes to how things are done.

- Asking for another inspection when ready.

Fixing these problems is key. Good responses show they care about safety.

Bold actions are needed for both situations. They help protect people from getting sick. They also show the place works hard to be safe and clean.

Credit: healizm.com

Conclusion: Fostering A Culture Of Compliance

Restaurants and food services aim for high health inspection scores. A culture of compliance is key. This means always following health rules. Let’s look at why passing health inspections matters so much.

Benefits Of Passing Health Inspections

Health inspections can be stressful. But, passing them has big perks. For starters, it means your place is safe. It also saves you from fines or closure. Good scores can lead to more customers too. They know you care about their wellbeing.

- Safe environment for both customers and staff

- Avoid fines and penalties that come with non-compliance

- Attract more customers with a reputation for cleanliness

- Peace of mind that you’re serving safe food

Building Trust With Consumers

Trust is everything in the food business. When you pass your health checks, people hear about it. They feel good eating at your place. They tell their friends too. This word-of-mouth can be better than any ad.

- Earn a reputation for health and safety

- Increase customer loyalty and word-of-mouth referrals

- Enhance staff morale and retention by providing a safe workplace

- Access to certifications and recognition for excellent health standards

Frequently Asked Questions

What Is A Point Of Focus During Health Inspections On Quizlet?

During health inspections on Quizlet, cleanliness, food handling, pest control, employee hygiene, and temperature control are focal points.

What Do Food Program Specialists Generally Focus On?

Food program specialists primarily focus on managing and implementing food service programs. They ensure nutritional guidelines are met and oversee food safety and distribution processes. Their role often involves coordinating with other professionals to enhance program effectiveness.

What Should A Manager Do During And After A Health Inspection?

During a health inspection, a manager should accompany the inspector, take notes, and ask for clarification on any points. After the inspection, they must review the results, devise a corrective action plan, and train staff on any necessary changes.

Which Of The Following Statements Are True About Safety And Health Inspections?

Safety and health inspections aim to identify workplace hazards. Employers must comply with relevant safety regulations. Regular inspections help prevent workplace injuries and illnesses. These inspections can lead to improved employee well-being and productivity.

Conclusion

Ensuring public safety is paramount during health inspections. Focus on cleanliness, food handling, and pest control. Regular compliance checks can prevent health hazards. Stay informed, heed regulations, and prioritize well-being. A rigorous health inspection safeguards our communities from avoidable risks.

Let’s stay proactive, ensuring healthful environments for all.